The Dangerous Goods Packaging Certificate is a core compliant document for dangerous goods export; without it, the loading and export of dangerous goods cannot be completed. However, most practitioners have an incomplete grasp of its full name and core information. The following is a standardized explanation from the perspectives of definition, core functions, applicable industries, handling procedures and precautions.

- Definition of Dangerous Goods Packaging Certificate: Not a Single Document

The Dangerous Goods Packaging Certificate is a general term for two types of statutory inspection documents, which together constitute the core basis for the compliance of dangerous goods export packaging:

- Inspection Result Sheet for the Performance of Import and Export Goods Packaging (referred to as “Performance Sheet”): Its core function is to prove that the packaging container itself has sufficient strength, tightness and safety protection performance, which can ensure that dangerous goods do not leak, break or other risks during transportation.

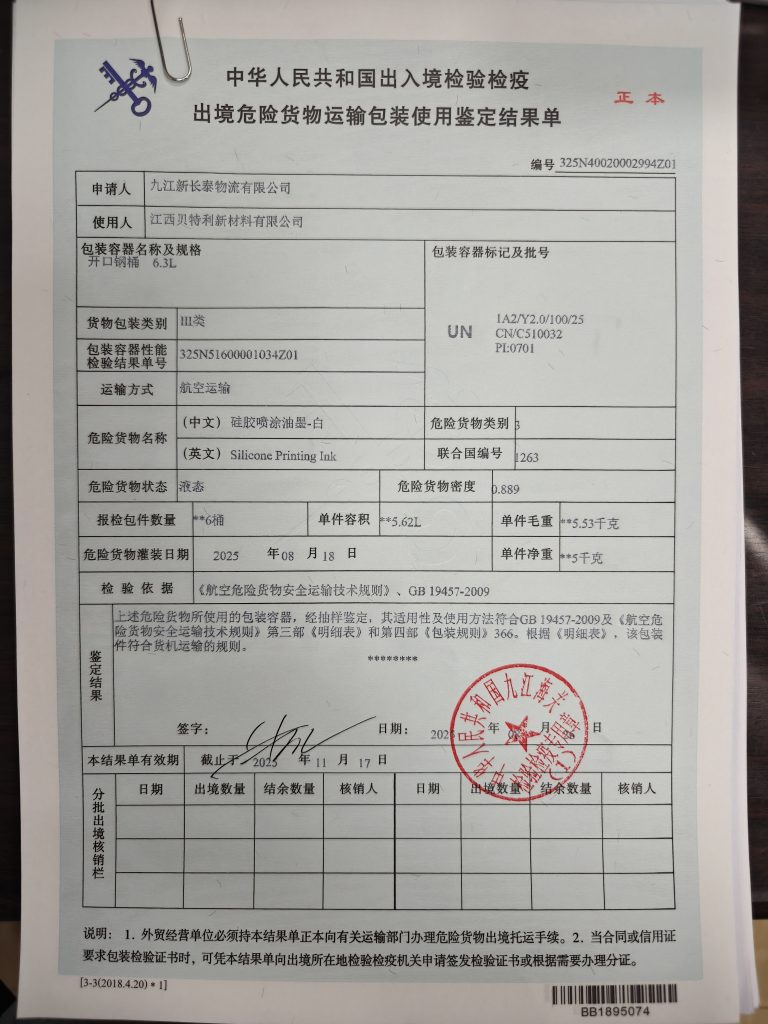

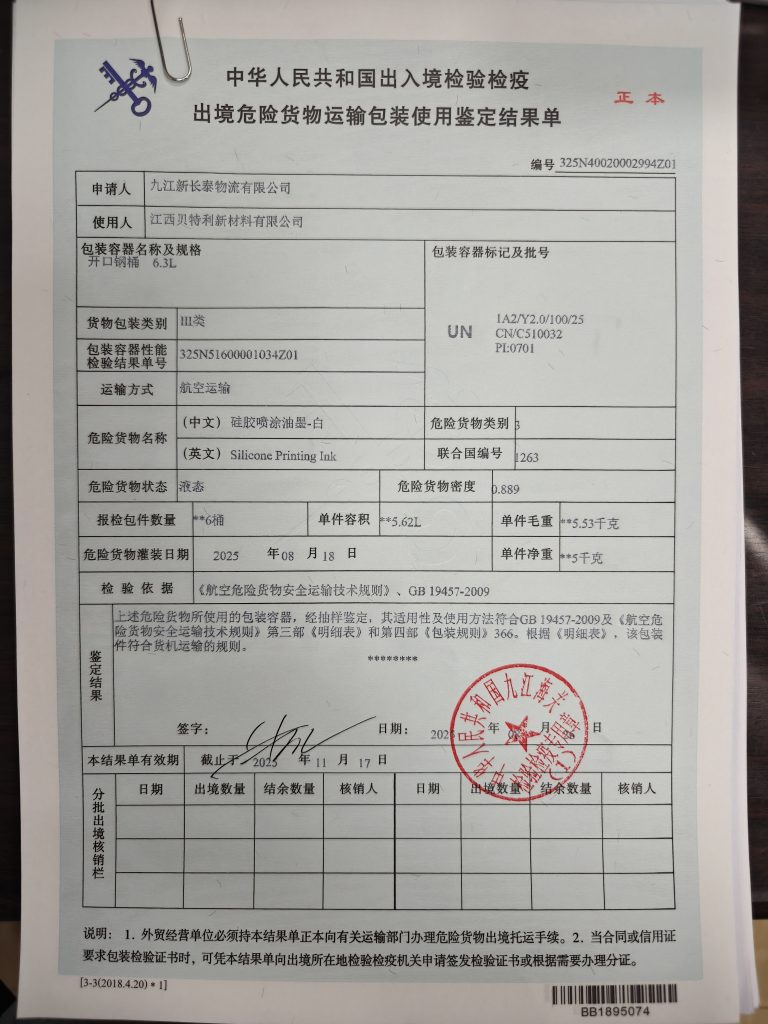

- Transport Packaging Use Inspection Result Sheet for Export Dangerous Goods (referred to as “Use Certificate”): Its core function is to prove the compatibility between specific dangerous goods and the packaging container used, confirm that the packaging method meets the safety requirements for long-distance transportation, and ensure the safety of dangerous goods throughout the transportation process.

- Core Functions of Dangerous Goods Packaging Certificate

- Basis for Export Acceptance: Enterprises must use the Use Certificate to prove to relevant departments that the dangerous goods packaging meets compliance requirements, which serves as a key document for export goods acceptance.

- Certificate for Port Release: Port supervision departments will verify whether the packaging is damaged, leaking or other problems based on the Dangerous Goods Packaging Certificate, and only goods that meet the requirements can be arranged for loading.

- Legal Compliance Guarantee: As an essential document for scenarios such as overseas investment and company registration, it can avoid compliance risks such as goods detention and fines due to non-compliant packaging.

III. Scope of Applicable Industries

All exported goods belonging to Class 9 Dangerous Goods (such as flammable liquids, corrosive substances, lithium batteries, etc.) must be provided with the Dangerous Goods Packaging Certificate. Common applicable industries include:

- Chemical industry: Solvents, coatings, pesticides, etc.;

- New energy industry: Lithium batteries, sodium batteries (UN3551 code added from 2025), etc.;

- Pharmaceutical/cosmetics industry: Alcohol disinfectants, sprays containing flammable gases, etc.;

- Daily chemical/electronic industry: Perfumes, power banks, electronic equipment containing lithium batteries, etc.

- Full Process and Precautions for Handling Dangerous Goods Packaging Certificate

(I) Step 1: Packaging Performance Inspection (Completed by Packaging Manufacturers)

Handling Process: Packaging manufacturers apply for an enterprise code from the customs → submit packaging samples for testing (including drop, air tightness, stacking and other items) → obtain the Inspection Result Sheet for the Performance of Import and Export Goods Packaging after passing the test.

Core Points: The packaging used must be marked with a compliant UN marking (such as UN1A1/Y1.4), which is a compliant “identity mark” for the packaging container and is indispensable.

(II) Step 2: Application for Use Identification (Completed by Export Enterprises)

- Necessary Materials:

– Inspection Result Sheet for the Performance of Import and Export Goods Packaging provided by the packaging manufacturer;

– Material Safety Data Sheet (MSDS) of the goods;

– Dangerous Characteristics Classification Identification Report of the goods;

– Packaging design drawings and physical samples.

- Handling Process: Submit the above materials to the customs at the enterprise’s location → on-site verification by the customs (verifying packaging specifications, compatibility between goods and packaging, etc.) → obtain the Transport Packaging Use Inspection Result Sheet for Export Dangerous Goods after passing the review.

(III) Tips on Common Risk Points

- Validity Period Control: The validity period of the Inspection Result Sheet for the Performance of Import and Export Goods Packaging is 1 year; the validity period of the Transport Packaging Use Inspection Result Sheet for Export Dangerous Goods is 1 year for sea freight and only 3 months for air freight. It needs to be re-applied if expired.

- Consistency of Enterprise Name: The enterprise name stated in the Dangerous Goods Packaging Certificate must be completely consistent with that on the customs declaration form, otherwise the goods will be detained.

- Consistency of Samples: The submitted packaging samples must be completely consistent with the actual export goods packaging (including size, material, specification, etc.). If there is any difference (such as a 5cm deviation in carton size), it will be directly judged as unqualified.